In the ever-evolving world of print technology, digital printing has emerged as a game-changer. From its humble beginnings to becoming a cornerstone of modern printing, digital printing has transformed how we think about and approach printed materials. Whether you’re a business owner, a designer, or just curious about the technology, this blog post will take you through the fascinating world of digital printing, its history, its applications, and why it’s so vital today.

Digital printing refers to the process of transferring a digital image directly onto various media surfaces without the need for a physical plate. Unlike traditional printing methods such as offset printing, digital printing is known for its efficiency, flexibility, and ability to produce high-quality prints on demand. Whether it’s business cards, brochures, banners, or even textiles, digital printing makes it possible to bring ideas to life quickly and accurately.

- On-Demand Printing: Ideal for quick turnarounds and small to medium print runs.

- Variable Data Printing: Each print can be customized with different images or text.

- Cost-Effective for Small Runs: No need for setup plates, making it economical.

- High-Quality Output: Produces vibrant, detailed images with consistent quality.

- Environmentally Friendly: Generates less waste and uses fewer chemicals.

-Inkjet Printing: Uses liquid ink sprayed through tiny nozzles onto the substrate. It's common in home printers and wide-format printing for banners, posters, and signage.

-Laser Printing: Uses toner (a fine powder) and a laser to produce images on paper. It’s fast and efficient, making it ideal for office printing and large-volume documents.

-Solid Ink Printing: This uses solid sticks of ink that are melted and jetted onto the substrate. Known for its vibrant colors, it's often used for high-quality graphic prints.

-Dye-Sublimation Printing: Transfers dye onto materials like fabric, plastics, or paper through heat. It’s commonly used for printing textiles, mugs, and other promotional items.

Digital printing may seem like a recent innovation, but its roots go back several decades. Let’s explore its journey:

The 1960s marked the beginning of digital printing with the development of the photocopier by Xerox and the invention of laser printing. These early technologies laid the groundwork for what would become the digital printing revolution.

In 1977, IBM introduced the first commercially successful laser printer, the IBM 3800, which was quickly adopted for high-volume printing tasks. By 1984, Hewlett-Packard had released the first desktop laser printer, the HP LaserJet, bringing high-quality printing into offices worldwide.

The 1990s saw significant advancements in digital printing. In 1991, Indigo, an Israeli company, unveiled the first digital offset color printer, the E-Print 1000, which used liquid ink to produce vibrant prints. This marked a turning point, as digital printing became a viable alternative to traditional methods.

Xerox further expanded the industry in 1993 with the DocuTech Production Publisher, setting a new standard for on-demand digital printing. By the late 1990s, wide-format inkjet printers were introduced, enabling large-format printing for posters, banners, and signage.

Digital printing has continued to evolve, offering faster speeds, higher quality, and more versatile applications. The rise of web-to-print services has also made it easier for customers to order customized prints online, while advancements in Variable Data Printing (VDP) have allowed for highly personalized marketing materials.

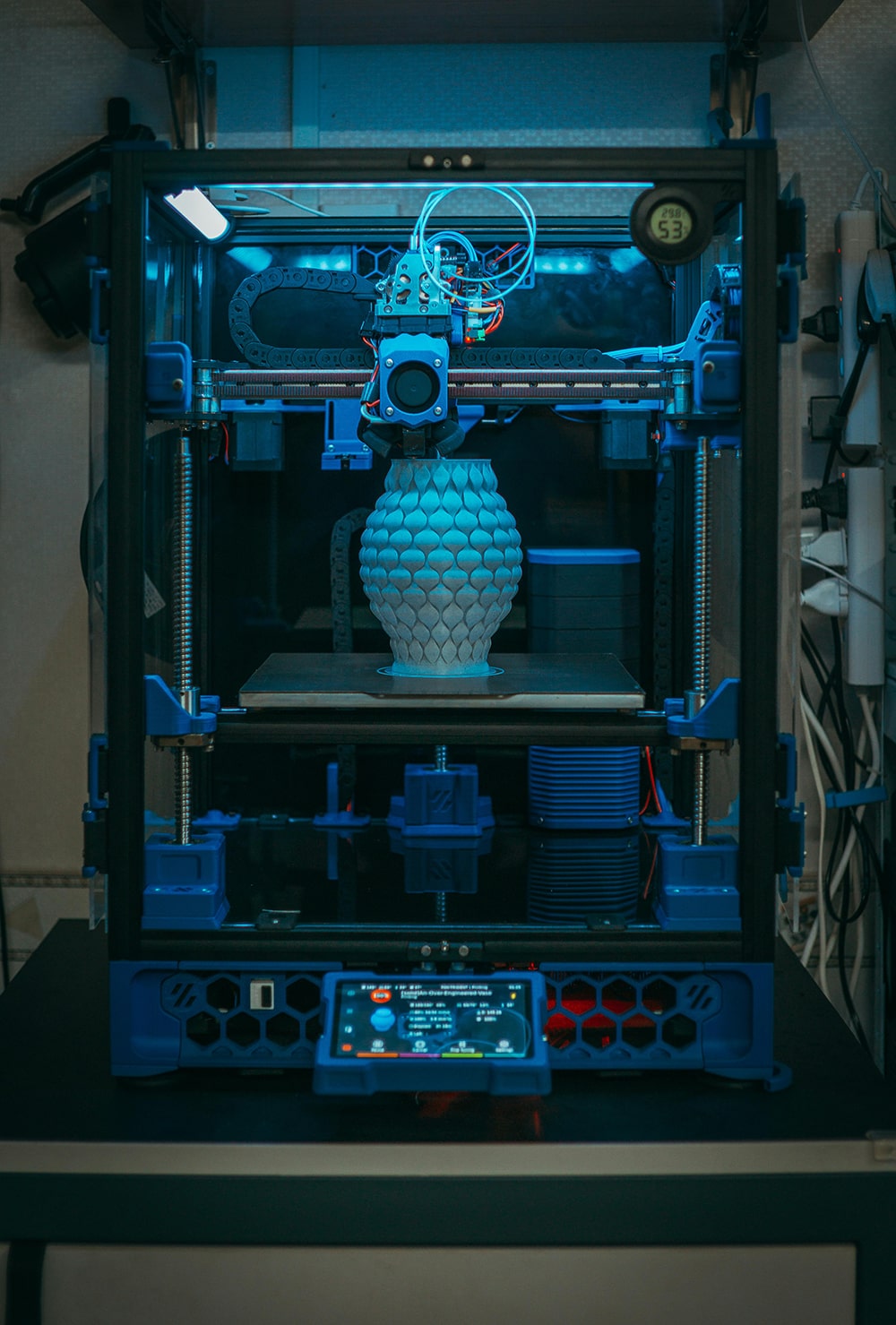

In recent years, another technological marvel has emerged alongside digital printing—3D printing. Unlike traditional digital printing, which produces images on flat surfaces, 3D printing creates three-dimensional objects by layering material based on a digital model. This revolutionary process is used across various industries, from manufacturing and medicine to art and fashion.

- Customization: Just like digital printing, 3D printing allows for highly personalized designs.

- Rapid Prototyping: Businesses can quickly create prototypes of products, speeding up the innovation process.

- Versatility: 3D printing can use various materials, including plastics, metals, and even biological substances.

The versatility of digital printing is one of its greatest strengths. Here are some of the most common applications:

- Marketing Materials: Flyers, brochures, and business cards are just the beginning. Digital printing allows for quick, cost-effective production of promotional materials that can be customized for different audiences.

- Personalized Products: From custom mugs and t-shirts to personalized packaging, digital printing makes it easy to create one-of-a-kind items.

- Large-Format Prints: Need a banner for an event or a poster for a trade show? Digital printing can produce high-quality large-format prints that stand out.

- Books and Magazines: On-demand printing has revolutionized publishing, making it possible to print short runs of books and magazines with ease.

- Textiles: Digital printing isn’t limited to paper. It’s also widely used in fabric printing, allowing for custom apparel, home décor, and more.

- Manufacturing: 3D printing is revolutionizing how products are made, allowing for the production of complex parts that are difficult to achieve with traditional methods.

- Medical: In the medical field, 3D printing is used to create customized prosthetics, implants, and even organ models for surgical planning.

- Art and Fashion: Artists and designers are using 3D printing to explore new creative possibilities, producing intricate jewelry, clothing, and sculptures.

Digital printing is more than just a convenient option—it’s a critical tool for businesses, marketers, and creatives alike. Its ability to produce high-quality, customizable prints quickly and affordably makes it ideal for everything from personal projects to large-scale marketing campaigns.

Additionally, digital printing is environmentally friendly. By eliminating the need for plates and reducing waste, it supports sustainable practices while still delivering excellent results.

3D printing, on the other hand, is transforming entire industries. Its ability to produce customized, complex objects quickly and efficiently is pushing the boundaries of innovation and creativity.

Digital printing has come a long way since its early days, evolving into a powerful tool that meets the demands of today’s fast-paced world. Whether you’re looking to print marketing materials, personalize products, or produce high-quality images on demand, digital printing offers unmatched flexibility, efficiency, and quality.

3D printing, with its ability to create three-dimensional objects from digital designs, represents the next frontier in printing technology. As these technologies continue to advance, their impact on the printing and branding landscape will only grow.

So, the next time you hold a beautifully printed brochure, receive a personalized package or see a 3D-printed object, remember—the magic behind it all lies in the advancements of digital and 3D printing.

Leave a Reply